Description

SBCG-P (Secure staking, slick side BCG, Manganese Phosphate) is the phosphated version of the original SBCG, which is NP3 coated.

It is our view that the factory M16 carriers are very good, and improvements over them would be hard to come by. Modern coatings have made them easy to clean and quite slick, which we can appreciate. NP3 coating is rather expensive and time consuming, which limits NP3 SBCG’s production to about 200 units a year. SBCG-P is identical to the NP3 SBCG, save for the coating of the bolt, carrier and SCP (SOTAR Cam Pin). SBCG-P is manganese phosphated, and uses black nitrided SCP.

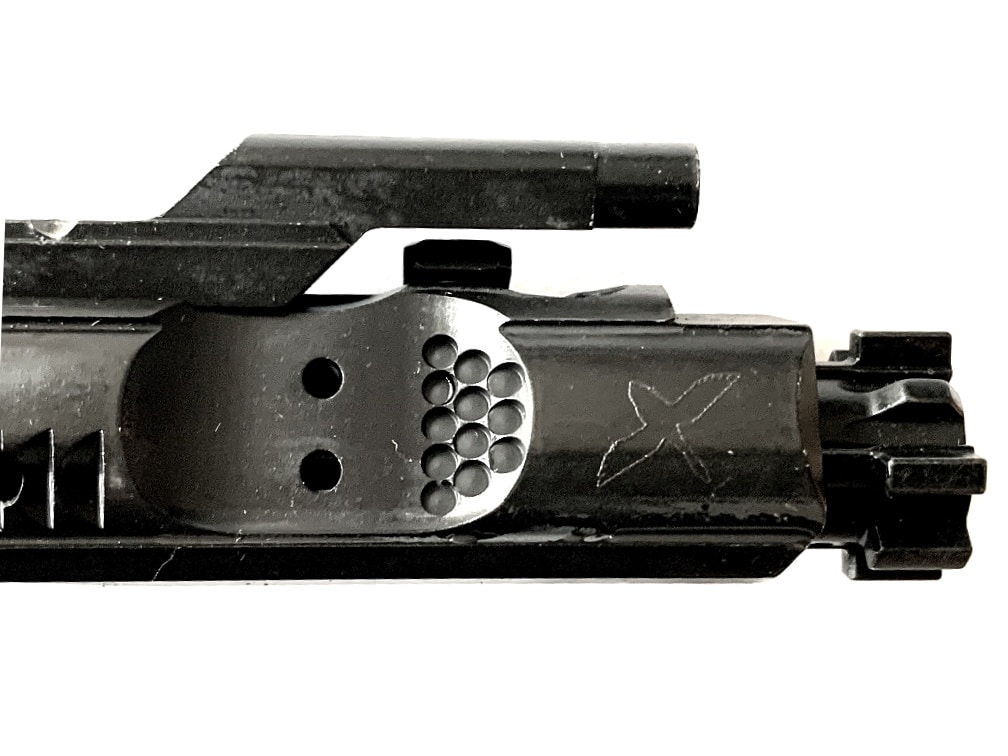

The S in SBCG stands for Secure Staking, Slick Side. SBCG carrier has a series of serrations or dimples to aid in closing an out of battery bolt on upper receivers without a forward assist. The carrier still has forward assist pawl notches, and so is compatible with forward assist equipped uppers.

The Secure Staking aspect involves SBCG’s use of Ned Christiansen’s OCKS (Optimized Carrier Key Screws), which when staked properly, offer significant improvement over conventional screws. OCKS have sharp, deep and effective knurling that extends to the top of the screw head. These splines form pockets for carrier key metal to flow into when the key is staked, resulting in gear tooth like engagement. Please go to this page for additional info and discussion

https://www.m4carbine.net/showthread.php?195130-On-loose-carrier-key-screwsSome argue that as long as the gas key screws are torqued to spec and staked properly, OCKS aren’t necessary. While I can’t argue with that, for us, it is a matter of over building in areas where providing another layer of fail safe and redundancy is worth the negligible cost. Given the numbers below, the choice of OCKS is an easy one to make.

Install torque spec is 50-58 in-lb

Removal torque spec is 55-100 in-lb

Testing consistently found removal torque of YFS screws averaging around 76 in-lb, with the OCKS consistently at 132 in-lb.

Since we’re so keen on the gas key’s staking to ensure its immobility, the question of one piece carrier had come up. It is our opinion that something different isn’t always something better. Gas keys can crack, and be dropped and damaged, debris or primer can find its way into the gas key. Our view is based on reality, not a theory, as all of these have happened. A conventional carrier with a separate gas key can simply have its gas key replaced, which is impossible for any one piece carrier.

Each SBCG has its firing pin protrusion checked, gas key torqued and staked, and is individually test fired. SBCG will ship as is, having been slightly lubed and dirtied by the test firing procedure.

Serrated or dimpled surface is machined in the concave area (forward of the gas vents of the carrier) to facilitate silent bolt closing on upper receivers without a forward assist.

SBCG carriers have a subdued and small Cygnus laser engraved. If you’re looking for in your face, billboard sized company logo, ours is not it. SBCGs are distinctive looking in their own right (form follows function, we didn’t go out of our way to make them look different), the subdued logo fits our philosophy and practice of modest to secret logo placement. It’s an identifier, not an advertising device.

* SBCG bolts are manufactured from Carpenter 158® Steel. Each Bolt is HP/MPI tested and inspected. Each bolt is shot peened and comes with a Sprinco heavy extractor spring and black spring insert.

* Shot Peened

* Sprinco 5-Coil Heavy Duty Extractor Spring

* Black Insert

* 100% HPT & MPI* SBCG carriers are 8620 steel and machined to USGI specifications. The M16/M4 carrier includes a mil-spec gas key. The gas key is heat treated per TDP specifications and NP3 coated. The gas key is secured to the carrier via OCKS (Optimized Carrier Key Screws), torqued to spec values, and properly staked.

* Manganese phosphate coated.