Description

NOTE:

Each package of MCF-A contains one MLOK cover with screws and MLOK nuts installed.

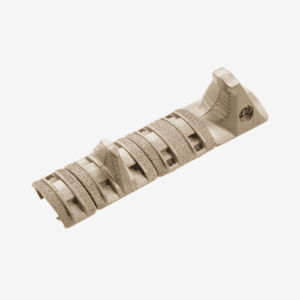

MCF-A is machined in 6061, with the AA surface (All Angles, or dimpled) pattern we developed for our bolt catch (ABC/R), forward assist (LDFA), ambidextrous magazine release (EMR-A). The AA concept was not developed for aesthetics, but as a versatile surface that offers equal traction from all angles of approach (thus the AA designation). The AA surface can hardly find a better application than hand guard rail covers, where a user’s hand can have multiple angles of approach, and hold the hand guard in different ways.

The AA pattern on the MCF is made of two dimple sizes and depths, a series of perforations that function both as drain holes and vents, are drilled along its length in the middle row of dimples.

To be sure, the use of aluminum as hand guard covers is a different approach to solving the problem of handguards heating up during and after firing. While polymer or wood insulates the user’s hands from the warm/hot handguard, MCF-A insulates, and draws and dissipates heat from the handguard.

These are the testing results:

* With strings of rounds fired, MCF-A heats up more slowly, and cools down much faster than the G10 variant.

* Sitting under direct Texas sun, then brought into 10 to 20 degrees cooler environments, G10 panel performs slightly better, but not appreciably so, with only 2 to 3 degrees of difference between the aluminum and G10 versions after a 5 minutes, and 10 minutes cool down.

The differences in MCF-A heat dissipation performance between live fire testing and left baking in direct sun light are related to the testing environments:

1. In live firing, the 3 o’clock and 9 o’clock mounted MCF-As are heated by the radiant heat from the barrel, but majority of the heat rises and is either absorbed by the hand guard’s 12 o’clock rail, or exists from the hand guard’s vents. In these tests, the rifle, hand guard, MCF-A and MCF G10 stayed in the same spot where the temperature didn’t fluctuate. The hand guard, MCF-A and MCF G10 cool at different rates, with MCF-A cooling faster than the hand guard and MCF G10.

2. In non-firing tests where MCF-A is in 12’clock position, left in direct sun light between 20 to 25 minutes, the rifle, hand guard, then MCF-A and MCF G10 are brought into a much cooler environment where the hand guard, MCF-A and MCF G10 all cool down at around the same rate.

The idea of using aluminum covers over aluminum hand guards must seem strange. As previously mentioned, MCF-A is different that it doesn’t simply insulate, but also dissipates heat generated by a hot barrel.

MCF-A is slightly thicker than the G10 version it replaces. MCF-A has greater surface area from the rows of dimples, and its through holes that were designed as drain holes, now function as vents. Combined, these features make MCF-A behave like a radiator.

MCF is available in two lengths: MCF-S (short, 3.2″, covers 2 MLOK slots) and MCF-L (long, 4.7″, covers 3 MLOK slots), both come standard with MLOK mounting hardware.

- Width: 0.600″

- Thickness: 0.152″

- Length: Long 4.7″ (3 MLOK slits), short 3.2″ (2 MLOK slots)

- Weight: Long .75oz per panel / Short .54oz per panel

- 1/8 Allen key required (not included)

- Torque value: 17 in/lb.

NOTE:

Each package of MCF contains one MLOK cover.

Each package of MCF contains one MLOK cover.